Saltwater Damage on Outboards — What We See Every Week

Saltwater is the single most destructive force acting on outboard engines in South Florida. Even well-maintained boats can develop serious issues when salt intrusion, heat, and humidity work together. While some damage is visible, much of the most expensive corrosion happens out of sight. These are the saltwater-related problems we see every week on South Florida outboards.

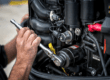

Internal Cooling System Corrosion

Cooling system corrosion is one of the most common and dangerous forms of saltwater damage. Salt deposits build up inside cooling passages, restrict water flow, and reduce heat transfer. Over time, this leads to overheating, warped components, and internal engine damage. Many engines that overheat repeatedly show significant internal corrosion long before any external signs appear.

Electrical Connection and Wiring Failures

Saltwater corrosion frequently attacks electrical connections, grounds, and wiring harnesses. Even small amounts of corrosion can cause sensors to malfunction, trigger warning alarms, or prevent engines from starting reliably. We routinely see engines with perfectly good mechanical components sidelined by electrical issues caused solely by salt exposure.

Rapid Anode Depletion

Anodes are designed to sacrifice themselves to protect critical engine components, but in South Florida they wear out quickly. Engines that go too long between inspections often have fully depleted anodes, leaving aluminum housings and internal components exposed to corrosion. Missing or heavily eroded anodes are one of the clearest signs that saltwater damage is actively occurring.

Seized or Sticking Components

Salt buildup and corrosion commonly cause thermostats, pressure relief valves, and trim components to stick or seize. When these parts fail to move as designed, cooling efficiency drops and engine stress increases. These issues often develop gradually, making them easy to miss until performance problems or alarms appear.

Fuel System Contamination

Saltwater environments accelerate fuel system issues by introducing moisture and corrosion into fuel lines, filters, and injectors. Ethanol-blended fuels compound the problem by absorbing moisture from humid air. This leads to poor combustion, hesitation, hard starting, and reduced engine efficiency if not addressed through routine maintenance.

External Corrosion Hiding Internal Damage

Visible corrosion on brackets, fasteners, and housings often signals more severe internal damage. Once corrosion is noticeable on the outside of an outboard, it is common to find corrosion deeper within the engine as well. Cosmetic corrosion is rarely just cosmetic in saltwater environments.

Why South Florida Outboards Are Especially Vulnerable

South Florida boats face constant exposure to salt, high temperatures, and humidity, often without long dry storage periods. Many engines are used year-round and stored outdoors, which prevents components from fully drying between outings. These conditions dramatically accelerate corrosion compared to freshwater or seasonal boating regions.

How Routine Maintenance Reduces Saltwater Damage

Regular outboard maintenance allows salt buildup and corrosion to be addressed before they cause permanent damage. Cooling systems can be flushed and inspected, anodes replaced, electrical connections cleaned and protected, and vulnerable components serviced proactively. Engines maintained on an aggressive schedule consistently show fewer saltwater-related failures.

Final Thoughts

Saltwater damage on outboards is not a matter of if, but when, especially in South Florida. The difference between a reliable engine and an expensive repair often comes down to how early corrosion and salt intrusion are addressed. Routine maintenance is the most effective way to protect your outboard from the damage we see every week on the water.